LE PROJET

SAVOIR-FAIRE

Dernière étape du processus.

Laisser la magie opérer…

C’est en réalité un peu plus complexe que ça, mais c’est la sensation qu’on a lorsqu’on envoie des dessins à nos usines au Portugal. Lorsqu’une simple idée grandit de jour en jour pour devenir un dessin. Puis un prototype. Puis une version finale quelques mois plus tard. Venez, on vous raconte tout.

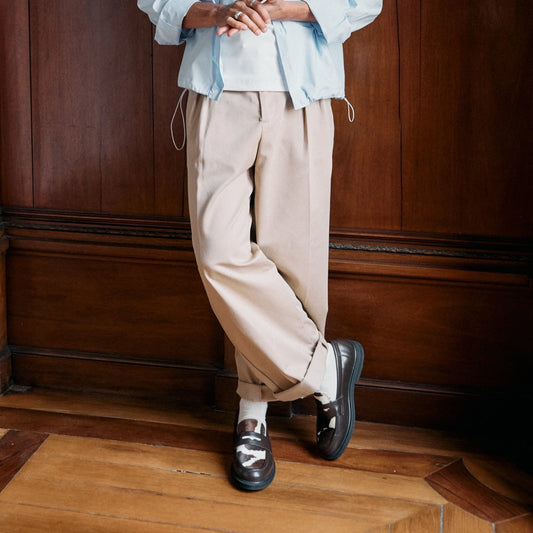

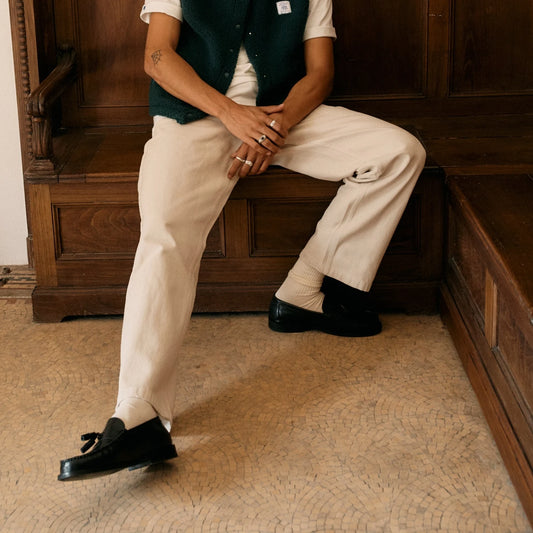

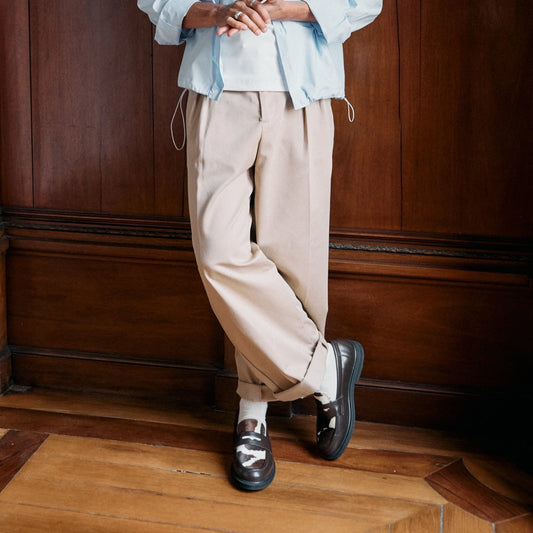

Made in Portugal.

Par ceux qui savent.

Point important : le Portugal c’est LE pays producteur de chaussures en Europe. Ils disposent d’un savoir-faire ancestral et reconnu, qui prit son envol dans les années 1970.

Aujourd’hui, nous sommes fiers de collaborer avec les meilleurs ateliers et les meilleurs artisans de la région : Tierri, Albano, Manuel, Licinia… Ils travaillent à Ovar et Vizela dans des ateliers familiaux dans le nord du Portugal, où le savoir-faire est transmis de génération en génération. Certains travaillent ici depuis plus de 30 ans et appliquent la même passion et la même qualité depuis le premier jour.

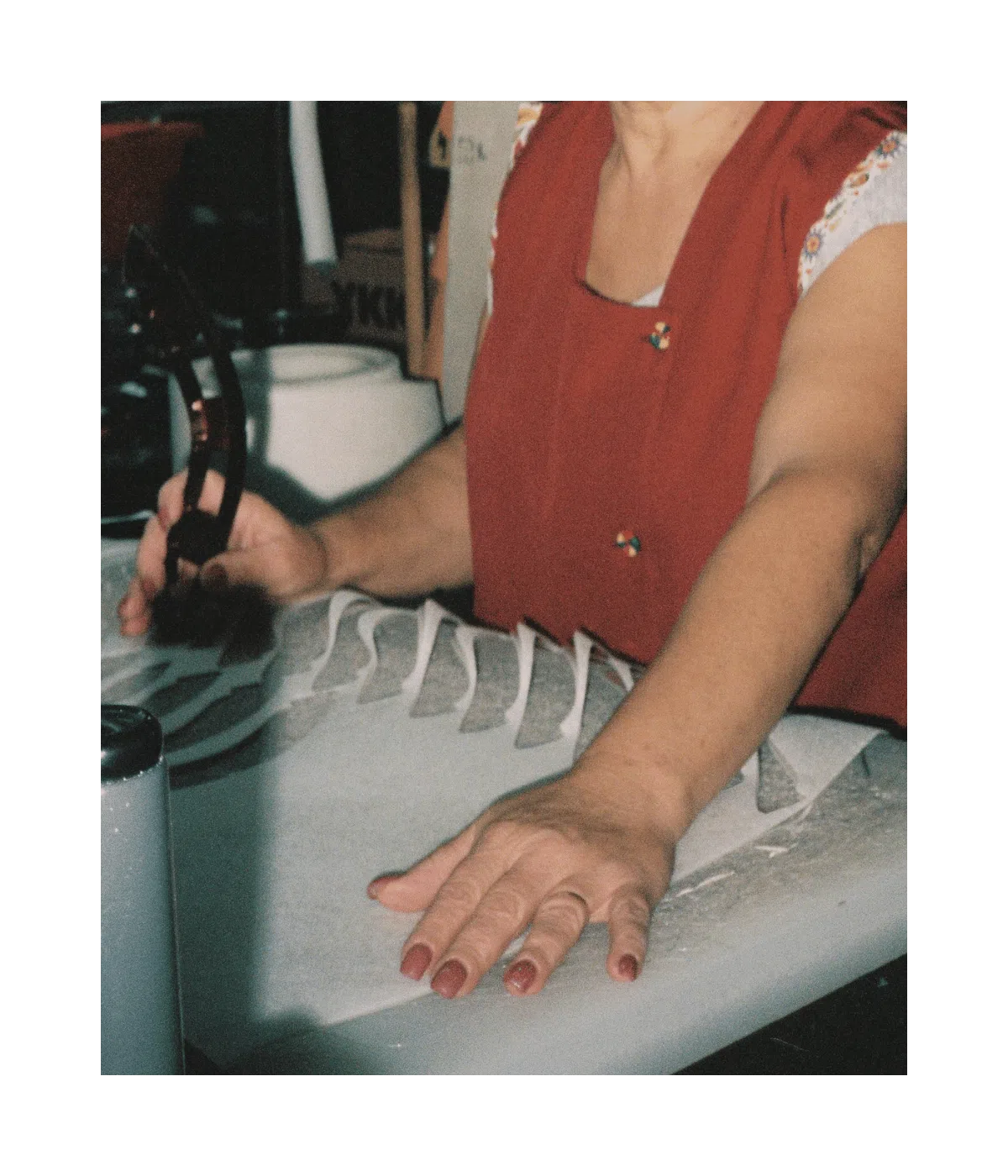

Assemblage 100% main.

Petites mains, grand talent.

Ici, aucune production de masse. Chaque paire est assemblée, vérifiée et testée à la main. Ce n’est donc pas 1% des produits qui sont vérifiés aléatoirement comme dans certaines usines (suivez mon regard…). Mais bien 100%. Chacune d’entre elles est alors méticuleusement questionnée, permettant de réduire au maximum les risques de défauts.

La différence entre un bon et un très bon produit ?

Son niveau de détail.

Mais pour accroître le niveau de détail, il faut y accorder du temps. À l’heure où les productions s’intensifient et s’accélèrent, nous faisons le choix de ralentir et de prendre le temps. Prendre le temps pour faire les choses bien et pour répéter nos gammes jusqu’à la perfection.

Pour vous donner un ordre d’idée, il faut entre 5 et 6 heures pour produire une paire. Elle passe de main en main et de poste en poste pour rencontrer une bonne vingtaine d’experts : découpe des empiècements, assemblage, collage de la semelle, contrôle à chaque étape et emballage... D’ailleurs la véritable expression n’est pas “Travail d’orfèvre” mais “Travail d’artisan d’Ovar”.

Miser sur le confort.

Enfin une chaussure à votre pied.

C’est en écoutant tous vos retours qu’on a compris le problème des baskets d’aujourd’hui. Elles font mal au pied après une journée. Et ne parlons pas du cas où vous la portez plusieurs jours d’affilée. On a donc fait du confort notre cheval de bataille :

• Semelle épaisse en caoutchouc recyclé, légèrement inclinée pour adopter la posture parfaite. Offrant plus d’amorti que la majorité des paires du marché.

• Intérieur en coton tissé, qui ne tient pas chaud, mais qui permet d’envelopper le pied d’une matière rembourrée et de le maintenir.

• Et le plus important : le test. Avant de sortir, chaque nouveau produit est testé en condition réelle pour s’assurer de sa robustesse et de son confort sur plusieurs mois. Si nous ne sommes pas pleinement satisfait, retour à l’étape sourcing matières et production pour recommencer.

Les nouveautés

-

NEW IN OLIVE LEATHER

NEW IN OLIVE LEATHERSoajo noir

Regular price $ 4,891.00 MXNRegular price$ 4,891.00 MXNSale price $ 4,891.00 MXN -

NEW IN OLIVE LEATHER

NEW IN OLIVE LEATHERSoajo vache

Regular price $ 5,027.00 MXNRegular price$ 5,027.00 MXNSale price $ 5,027.00 MXN -

NEW IN OLIVE LEATHER

NEW IN OLIVE LEATHERBraga noir

Regular price $ 4,891.00 MXNRegular price$ 4,891.00 MXNSale price $ 4,891.00 MXN -

NEW IN OLIVE LEATHER

NEW IN OLIVE LEATHERMinho noir - blanc

Regular price $ 4,891.00 MXNRegular price$ 4,891.00 MXNSale price $ 4,891.00 MXN -

NEW IN OLIVE LEATHER

NEW IN OLIVE LEATHERGaia noir

Regular price $ 3,669.00 MXNRegular price$ 3,669.00 MXNSale price $ 3,669.00 MXN -

NEW IN OLIVE LEATHER

NEW IN OLIVE LEATHERSoajo marron

Regular price $ 4,891.00 MXNRegular price$ 4,891.00 MXNSale price $ 4,891.00 MXN -

NEW IN OLIVE LEATHER

NEW IN OLIVE LEATHERDouro vache

Regular price $ 5,027.00 MXNRegular price$ 5,027.00 MXNSale price $ 5,027.00 MXN -

NEW IN

NEW INGaia vache

Regular price $ 3,804.00 MXNRegular price$ 3,804.00 MXNSale price $ 3,804.00 MXN -

NEW IN OLIVE LEATHER

NEW IN OLIVE LEATHERMinho noir

Regular price $ 4,891.00 MXNRegular price$ 4,891.00 MXNSale price $ 4,891.00 MXN -

NEW IN OLIVE LEATHER

NEW IN OLIVE LEATHERDouro noir - blanc

Regular price $ 4,891.00 MXNRegular price$ 4,891.00 MXNSale price $ 4,891.00 MXN -

NEW IN OLIVE LEATHER

NEW IN OLIVE LEATHERDouro marron

Regular price $ 4,891.00 MXNRegular price$ 4,891.00 MXNSale price $ 4,891.00 MXN -

NEW IN OLIVE LEATHER

NEW IN OLIVE LEATHERDouro noir

Regular price $ 4,891.00 MXNRegular price$ 4,891.00 MXNSale price $ 4,891.00 MXN -

NEW IN OLIVE LEATHER

NEW IN OLIVE LEATHERBraga noir - blanc

Regular price $ 4,891.00 MXNRegular price$ 4,891.00 MXNSale price $ 4,891.00 MXN -

NEW IN OLIVE LEATHER

NEW IN OLIVE LEATHERBraga bordeaux

Regular price $ 4,891.00 MXNRegular price$ 4,891.00 MXNSale price $ 4,891.00 MXN