Grape leather, what is it?

Share

Grapes are more generally found in liquid form as an aperitif... and yet! Since September, grapes have adorned our Zèta sneakers.

Grape leather, kezako?

Making recycled, recyclable and vegan sneakers is the challenge that Zèta has set itself for a year. Laure, the founder, wanted to find a solution that would allow the creation of designer sneakers while limiting the creation of new materials, in order to limit waste as much as possible. Grape faux-leather then seemed to be the perfect choice. Zero waste yes, but vegan is even better.

Making Grape Leather

While a few years ago, it was unthinkable to find all kinds of alternatives to materials that were not very respectful of the environment, today it is the bet of a good number of companies that throw themselves into adventure. Grape leather is a vegetable leather made from all the materials that remain after the harvest and cannot be used. This is what is called grape marc in viticulture: the skin of the grapes, the pips, the branches or even the stems.

Imagined and designed in Bordeaux, it seemed obvious to us that our first collection to be made from grape leather. Choosing an innovative and responsible alternative to animal leather is the commitment of the Zèta brand. The wine is for you, and the waste is for us!

Step 1: Grape Marc Collection

Each year, during the harvest, the grape juice is extracted in order to carry out the vinification. The grape marc, in other words the skin, pips and other residues, are recovered.

Step 2: Drying and Grinding

The marc will then be dried in ovens to extract all the moisture, then ground into a fine powder.

Step 3: Add materials

The fine powder obtained will then be added to a base made up of vegetable oil and water-based PU (25%), the objective being to solidify the material and ensure its resistance over time.

Step 4: Spreading and Dyeing

The thick white paste obtained will be dyed according to the desired colors then spread in large strips in order to proceed with drying.

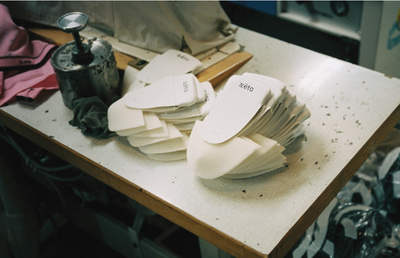

Step 5: Cut and assemble

There you go!

all that remains is for our craftsmen to cut out the material using cookie cutters in order to assemble them to transform them into Alpha pairs.